Background

The Femometer Smart Ring project was initiated in late 2022 to address a fundamental limitation in traditional fertility tracking.

Basal Body Temperature (BBT) measurement—one of the most reliable physiological indicators for ovulation confirmation—typically requires users to wake up at a fixed time each morning to take an oral temperature reading. In practice, this workflow introduces significant friction: it disrupts sleep, is easy to forget, and produces unreliable data when sleep quality is poor or irregular. Over time, these issues lead to inconsistent tracking and reduced long-term adherence.

The core objective of this project was to eliminate that behavioral burden by introducing a passive, overnight wearable that enables “sleep freedom”—automatically capturing temperature signals during sleep to support ovulation prediction and confirmation. Strategically, the product was positioned to compete with devices such as the Ava Bracelet, with an initial focus on women aged 20–40 in the US and European markets.

My Role

As Co-Founder and Product Director, I led the end-to-end definition and execution of the Femometer Smart Ring. My responsibilities spanned user research, product strategy, hardware specification trade-offs, algorithm direction, and cross-functional coordination across industrial design, firmware, data science, and manufacturing partners.

Product Design

Product Concept Exploration

Product Concept Exploration

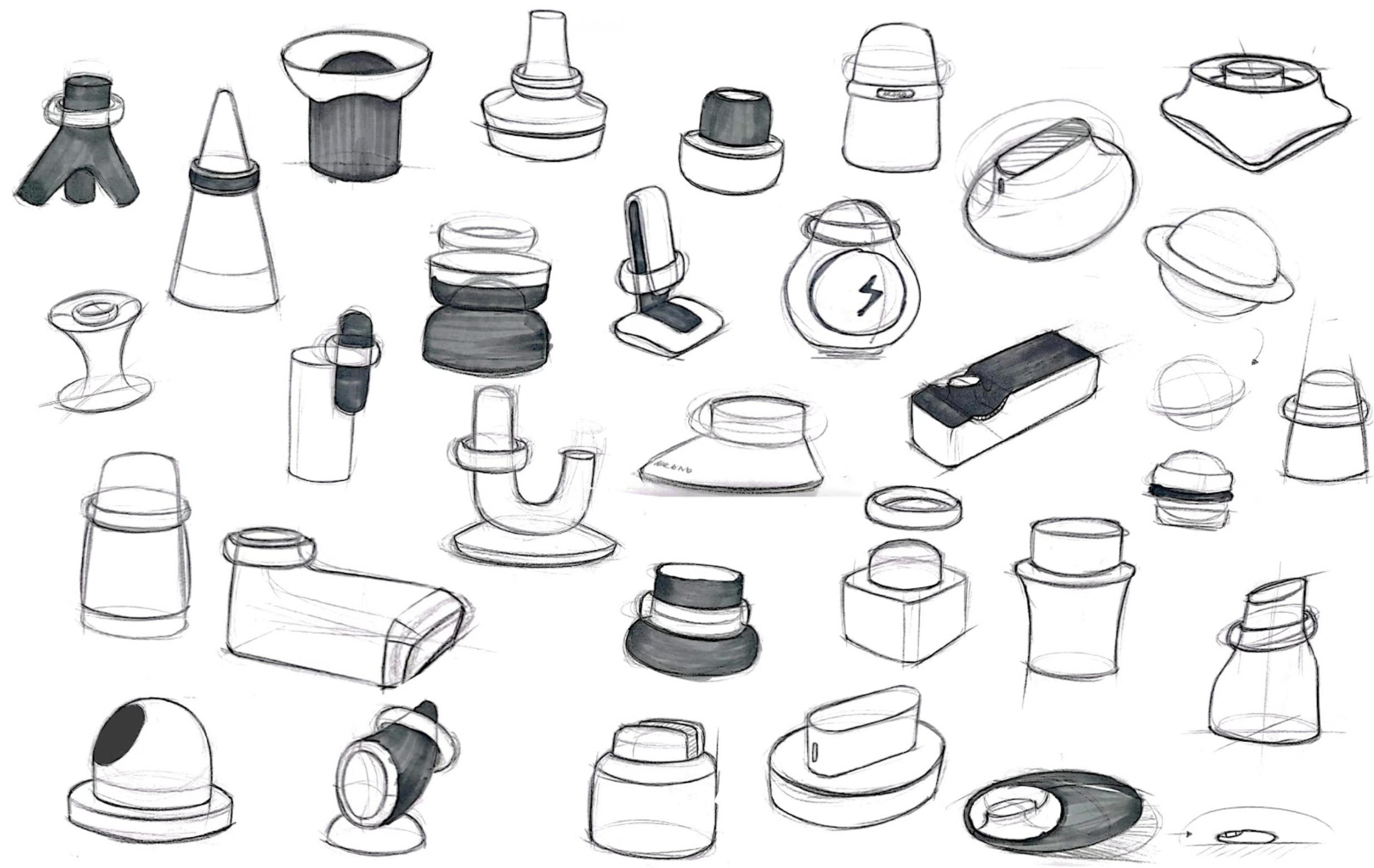

Early user research consistently showed that while accuracy was a non-negotiable requirement, behavioral friction was the primary reason users failed to sustain BBT tracking over time. This insight directly shaped the product’s core design principle: fertility tracking must work passively, without requiring conscious daily action.

Users also emphasized that the device needed to be discreet, small, subtle, and comfortable, particularly for overnight wear. Based on these insights, the product was designed as a smart ring supporting multiple US ring sizes and integrating temperature, infrared, and sleep monitoring sensors.

To reach a broad consumer audience, the project operated under strict cost and manufacturability constraints. These constraints heavily influenced decisions around component selection, materials, power management, and assembly processes, requiring continuous trade-offs between performance, comfort, and scalability.

System Design

Prototypes at Different R&D Stages

Prototypes at Different R&D Stages

The Femometer Smart Ring was designed as a continuous physiological sensing system, optimized for passive overnight data collection under tight physical, power, and manufacturing constraints.

At a high level, the system architecture consisted of four tightly coupled layers:

Sensing Layer

The ring integrated temperature, infrared, and several other sensors to capture distal body temperature and micro-movement signals during sleep. Finger-based sensing provided higher thermal sensitivity than wrist-based wearables, but also introduced greater signal variability due to peripheral blood flow dynamics.On-Device Processing & Power Management

Given the ultra-small form factor, firmware design emphasized low-power sampling strategies, sensor duty cycling, and stable data buffering. Hardware and firmware decisions were continuously evaluated against battery life, thermal stability, and long-term wear comfort.Signal Processing & Algorithm Layer

Raw sensor data flowed through a multi-stage pipeline, including noise filtering, sleep-period segmentation, and temperature trend extraction. A key challenge emerged when existing sleep and temperature algorithms—largely derived from wrist-based research—proved unreliable when applied to finger-based signals, requiring new data collection and algorithm adaptation.Manufacturing & Scalability Layer

The physical realization of the ring placed strict limits on material choice and assembly techniques. Advanced approaches such as ceramic outer and metal inner structures were explored to balance durability, comfort, signal stability, and manufacturability. Achieving acceptable yield across multiple ring sizes required close iteration between design assumptions and factory feedback.

Across these layers, the team navigated persistent tensions between signal reliability and comfort, algorithm ambition and data maturity, and engineering feasibility and manufacturing reality. Progress came through iterative convergence rather than a single breakthrough, resulting in a validated system architecture suitable for first-generation deployment.

Takeaways

This project shaped how I now approach the design of wearable health systems:

Architecture precedes features

In highly constrained hardware products, early architectural decisions dominate long-term outcomes. Late-stage feature additions can destabilize the entire system.Algorithms are not inherently transferable

Physiological models are deeply dependent on sensor placement, form factor, and user behavior. Literature-proven approaches should be treated as hypotheses, not guarantees.Data feasibility must come before model sophistication

Advanced algorithms add value only after signal quality and stability are validated through domain-specific data collection.Manufacturing is part of the product

Materials, assembly methods, and yield behavior define what is realistically achievable. Manufacturing considerations must be integrated from the earliest design stages.Process discipline enables speed

Written specifications, versioned change logs, and explicit ownership are not overhead—they are prerequisites for efficient iteration in cross-functional hardware–software teams.